- #Reflow soldering at home serial

- #Reflow soldering at home portable

- #Reflow soldering at home license

- #Reflow soldering at home free

#Reflow soldering at home license

This Project is designed under General Public License V3.0 See LICENSE.txt for more information. ISSUE: Alluminum would act as heatsink not letting the plate to heatup/quick cooldowns. In near future, it is desired to implement the same Idea on Alluminum Base PCBs.

This Hotplate is based on Regular FR4 materials that degrade over time due to excessive heating. Push to the Branch (git push origin feature/Feature).Commit your Changes (git commit -m 'Add some Features').Create your Feature Branch (git checkout -b feature/Feature).Don't forget to give the project a star! Thanks again! You can also simply open an issue with the tag "enhancement". If you have a suggestion that would make this better, please fork the repo and create a pull request. Any contributions you make are greatly appreciated. (In such case, desolder the Temperature sensor and extend it to the bottom of the hotplate using wires).Ĭontributions are what make the open source community such an amazing place to learn, inspire, and create.

#Reflow soldering at home free

If Temperatures Higher than 270C are desired, feel free to breakdown/cutdown the Controller portion and Heating Element to avoid controller assembly meltdown. Any Forced Cooldown solution is highly NOT RECOMMENDED as it reduces the Life of FR4 material. Give Hotplate Enough time to Heatup and cooldown. Power Up the Board using a PSU with 6-12V 2A Ratings. The ARDUINO IDE can be used to Program the Microcontroller.

#Reflow soldering at home serial

Program the Microcontroller using CP210x/CH340x/FTDI based USB to serial converters.

It is requested to please Open up an Issues if there is any stock outage or Manufacturing Problems. OR If you wish to order assembled PCBs, I optimized the BOM to make it super smooth and easy to source components. After opening the Project in KiCAD, you can just scroll through the BOM and place components with respect to their designators. It is super convenient to assemble the Hardware & Components specially if you ordered the Stencil alongwith PCBs. So, I came up with a backup plan and designed it in a way you can just cut the controller portion away from the coil area and use the controller with any OFF the SHELF heating element like aluminum plates. The standard PCB material is FR4 which is very reliable in handling higher temperatures but it may not be very long lasting if being used very often.

#Reflow soldering at home portable

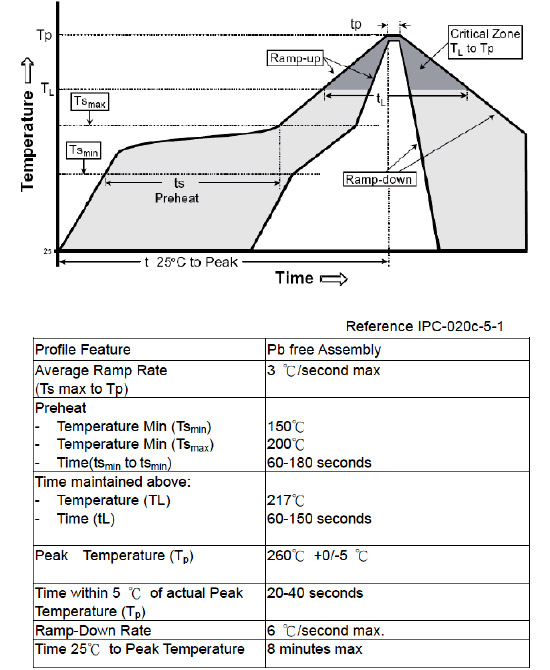

This makes it highly portable and Tweakers friendly. The advantange is that you can use it either as a whole system by simply plugging the power in and starting the system OR You can detach the controller and Coil area of the PCB (separated by cut-lines). This board is created considering all the potential issues and major use cases. The temperature sensor continously reads the temperatures and sends back to the Microcontroller. The hOtpLaTe r0.1 manages to acheive this temperature curve by adjusting the switching duty of MOSFET which results in variation in heat. Below is the proper reflow curve a heater should achieve for perfect soldering of components. The temperature curve provides an intuitive method to analyze the temperature change of a component during the entire reflow soldering process.

The reflow curve of the temperature of a certain point on the SMA with time when the SMA passes through the reflow oven furnace. Heating may be accomplished by passing the assembly through a reflow oven. The solder paste reflows in a molten state, creating permanent solder joints. Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to temporarily attach one or thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. UI with LCD and Pushbuttons for controlling the system.This device is created as a Low-Cost solution for DIY reflow assembly of SMD components.

0 kommentar(er)

0 kommentar(er)